Modern Machinery and Infrastructure

Our plant is located in a 1,00,000 sqft plot, at seven-star Additional Ambernath MIDC, Mumbai. The MIDC has with concrete road connectivity, pipeline gas service, 24×7 electric connectivity with NTPC grid and has anchor plants of Godrej and CEAT.

We employ automated loading and nitrogen bubbling which reduces smelting time and iron content. Also, we use a tilting furnace which drains higher purity aluminium metal from the top, thus increasing metal quality.

Similar to technology used by NALCO, we use hot top casting which provides superior aluminium grain structure. We also employ “End cutting of aluminium billets” to reduce bubbling during extrusion process.

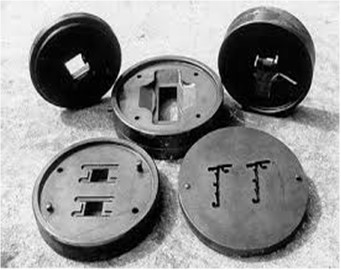

Dies are made using high quality H13 imported forged steel, and undergo vacuum heat treatment to maintain dimensional integrity.

Extrusion presses are made with pre-stressed tie rods, which increase press stability and provide better profile accuracy. Also, we our presses are specially designed for Indian climate with enhanced heat exchange systems.

Automated handling system limits human interaction with finished product, reducing scratch marks. Also, use of high temperature felts reduces dents and handling damages.